Dry Cryogenic Couplings

Dry Cryogenic Couplings are designed for use of cryogenic applications/medias such as LNG and Nitrogen and other liquefied gases.

The DCC coupling is suitable for the loading and unloading of cryogenic liquefied gases, such as LNG, nitrogen, oxygen, argon, ethylene, down to -196° C.

A quick and safe connection of hoses and loading arms under pressure and with minimized product loss. During the cool down phase no retightening of the connection is necessary as practiced with flanged or threaded connections.

Dry Cryogenic Couplings according to ISO 21593 and ISO TS 18683.

| Size from: | 1” to 8” |

| Material: | Stainless Steel |

| Seals: | PTFE |

Available with threaded and flanged connections, for both hose unit and tank unit.

Benefits

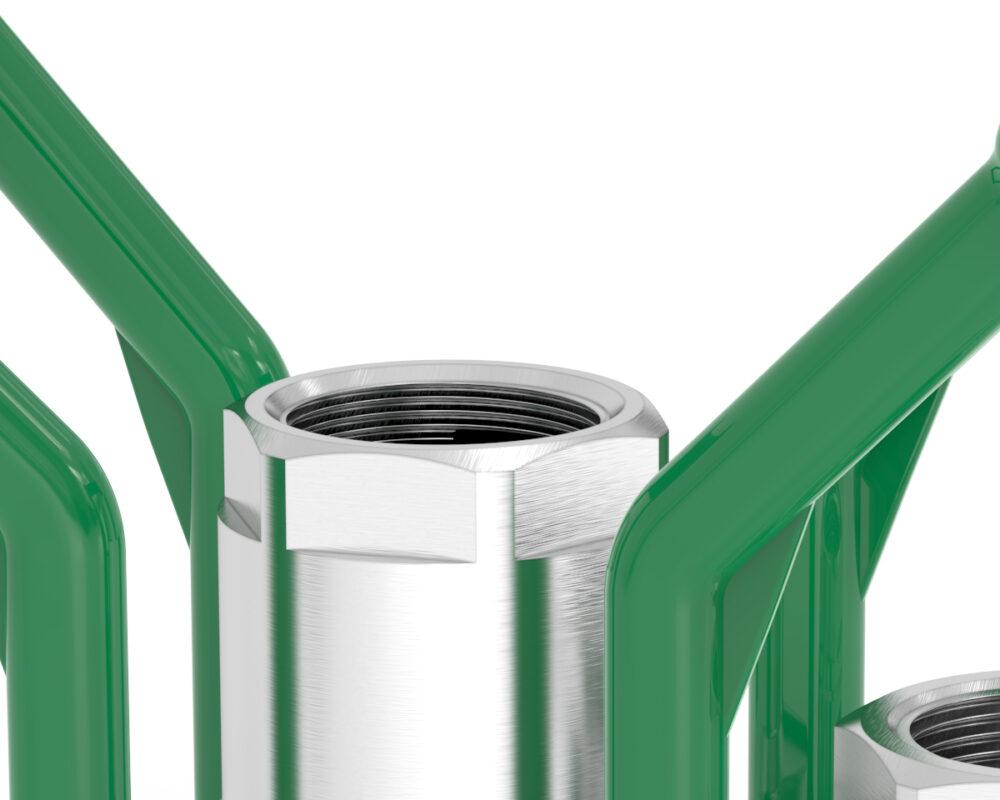

Handle

Powerful handle - many alternatives to fit specific use.

Connections

Large variety of connections (both thread and flange) for mounting directly on hose or tank.

Weight

Weight optimized.

Integrated swivel

Dry Cryogenic coupling with integrated swivel.

Cam curve

Inner cam curve (protected from external impact).

Technical data

| Socket | Threaded connections | Flanged connections | Flow rate | Materials | Seals | ||

|---|---|---|---|---|---|---|---|

|

1” (DN25) | 56 mm | NPT | ANSI & EN | Up to 250 L/min | Specified in configurator | PTFE |

|

2” (DN50) | 70 mm | NPT | ANSI & EN | Up to 900 L/min | Specified in configurator | PTFE |

|

2½” (DN65) | 105 mm | NPT | ANSI & EN | Up to 2.100 L/min | Specified in configurator | PTFE |

|

3” (DN80) | 119 mm | NPT | ANSI & EN | Up to 2.800 L/min | Specified in configurator | PTFE |

|

4” (DN100) | 164 mm | NPT | ANSI & EN | Up to 7.000 L/min | Specified in configurator | PTFE |

|

6” (DN150) | 238 mm | NPT | ANSI & EN | Up to 14.000 L/min | Specified in configurator | PTFE |

|

8” (DN200) | 314 mm | NPT | ANSI & EN | Up to 24.000 L/min | Specified in configurator | PTFE |

Service

Service guidance

Service guidance for a MannTek Dry cryogenic coupling.

Innovative accessories

Colour coding

For a clear assignment of coupling and medium, the body, flange and handles of our…

Read more

Stop before disconnect

This is a feature for detecting eventual leakage before disconnecting the hose and the tank…

Read more

Hose unit with electronic sensor

The sensor detects whether the valves are in an open or closed position. The signal…

Read more

Locking device

Option for hose units. Once coupled, the connection is automatically locked and can not loosen…

Read more

Dust cap and dust plug

Dust plug to protect the couplings against the ingress of dirt and water.

Read more

Heated parking device

Heated parking device is used to easily defrost and dry the hose unit after LNG…

Read more

Parking device

For safe and dedicated storage of hose unit. Available with or without parking sensor.

Read more