Dry Gas Couplings

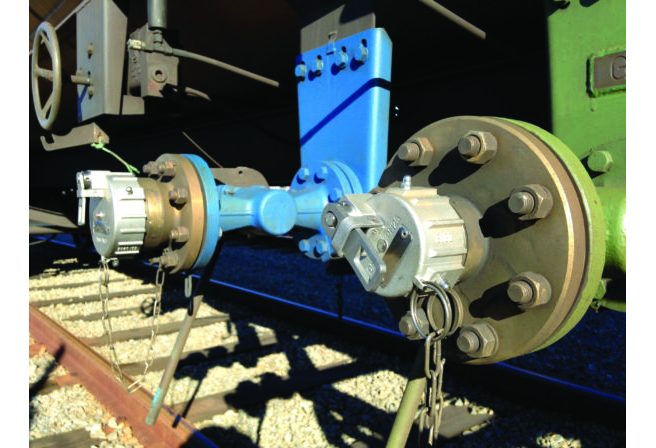

Dry Gas Coupling are used for loading and unloading of liquefied petroleum gas LPG and various other gaseous media.

The DGC couplings are optimized for connection and disconnection at higher working pressure (up to 25 bar).

| Size from: | 1” to 8” |

| Material: | Stainless Steel |

| Seals: | FKM/LT |

| Working pressure | 25 bars |

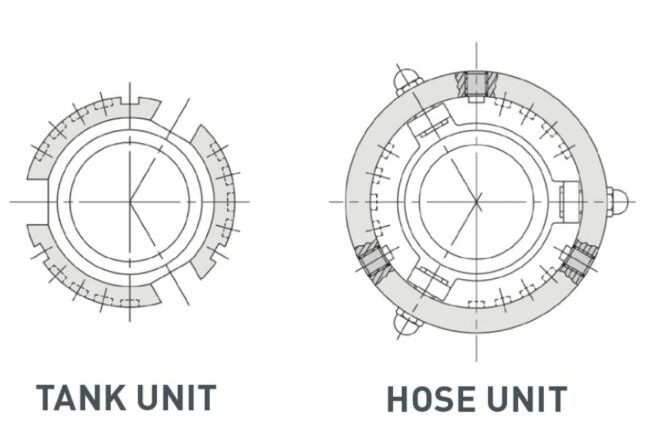

Available with threaded and flanged connections, for both hose unit and tank unit

Benefits

Handle

Powerful handle - many alternatives to fit specific use.

Sealing

Unique low temp FKM sealing technology for all qualities of LPG and temperatures operational.

Connections

Large variety of connections (both thread and flange) for mounting directly on hose or tank.

Rubber protecting ring

Robust rubber protecting ring - weather-resistant and electrically non-conductive.

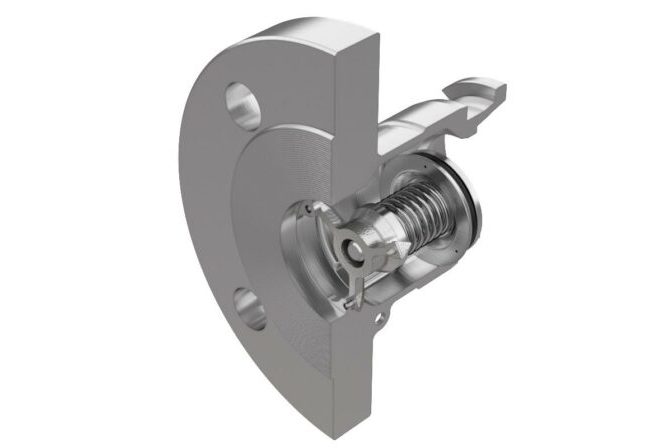

Integrated swivel

Dry gas coupling with integrated swivel.

Cam curve

Inner cam curve (protected from external impact).

Weight

Weight optimized.

Technical data

| Socket | Threaded connections | Flanged connections | Flow rate | Materials | Seals | ||

|---|---|---|---|---|---|---|---|

|

1” (DN25) | 56 mm | ¾”, 1”, 1¼” BSP, NPT, ACME | ANSI & EN | Up to 250 L/min | Specified in configurator | FKM/LT |

|

2” (DN50) | 70 mm | 1½”, 2” BSP, NPT, ACME | ANSI & EN | Up to 900 L/min | Specified in configurator | FKM/LT |

|

3” (DN80) | 119 mm | 3” BSP, NPT, ACME | ANSI & EN | Up to 2.800 L/min | Specified in configurator | FKM/LT |

|

4” (DN100) | 164 mm | 4” BSP, NPT, ACME | ANSI & EN | Up to 7.000 L/min | Specified in configurator | FKM/LT |

|

6” (DN150) | 238 mm | 6” BSP, NPT, ACME | ANSI & EN | Up to 14.000 L/min | Specified in configurator | FKM/LT |

|

8” (DN200) | 272 mm | 8” NPT, ACME | ANSI & EN | Up to 23.000 L/min | Specified in configurator | FKM/LT |

Service

Service guidance

Service guidance for a MannTek Dry gas coupling.

Innovative accessories

Colour coding

For a clear assignment of coupling and medium, the body, flange and handles of our…

Read more

Stop before disconnect

This is a feature for detecting eventual leakage before disconnecting the hose and the tank…

Read more

Selectivity (coding) system

To prevent accidental mixing of media, a selectivity (coding) system for DDC is available. Tank…

Read more

Hose unit with electronic sensor

The sensor detects whether the valves are in an open or closed position. The signal…

Read more

Locking device

Option for hose units. Once coupled, the connection is automatically locked and can not loosen…

Read more

Hose unit with integrated breakaway

If there is a risk of excessive force on the hose unit due to unexpected…

Read more

Pressure equalizing valve

If liquid is trapped behind the tank unit, due to a closed valve or the…

Read more

Pressure bleeding valve

For special operating conditions where there is the risk of excessive pressure increase through warming…

Read more

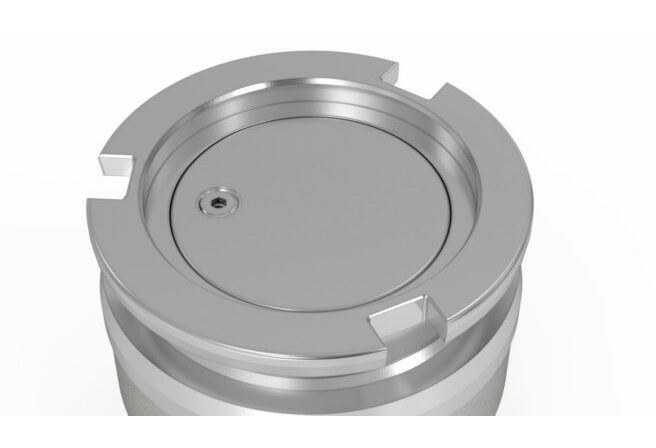

Tank unit with eccentric flanges

Tank units/adapters with eccentric flanges are available in sizes 1” to 6”. Eliminate risks of…

Read more

Safety pressure cap

Contains pressure with built in warning indicators for excessive pressure. Design allows operators to release…

Read more

Open/close indicator

Shows in which direction the coupling should be turned. Indicates the end positions whether the…

Read more

Safety pressure plug

Contains pressure with built in warning indicators for excessive pressure. Design allows operators to release…

Read more

ACME and whitworth threads

DGC tank units and hose units are available with ACME and whit worth threads for…

Read more

Dust cap and dust plug

Dust plug to protect the couplings against the ingress of dirt and water.

Read more

Parking device

For safe and dedicated storage of hose unit. Available with or without parking sensor.

Read more

None projecting pistons

When coupled, the piston spindle does not protrude. This special type is e.g. useful when…

Read more