Dry Evotek Couplings

A range of dry couplings which have been developed especially for use in the chemical and pharmaceutical industry.

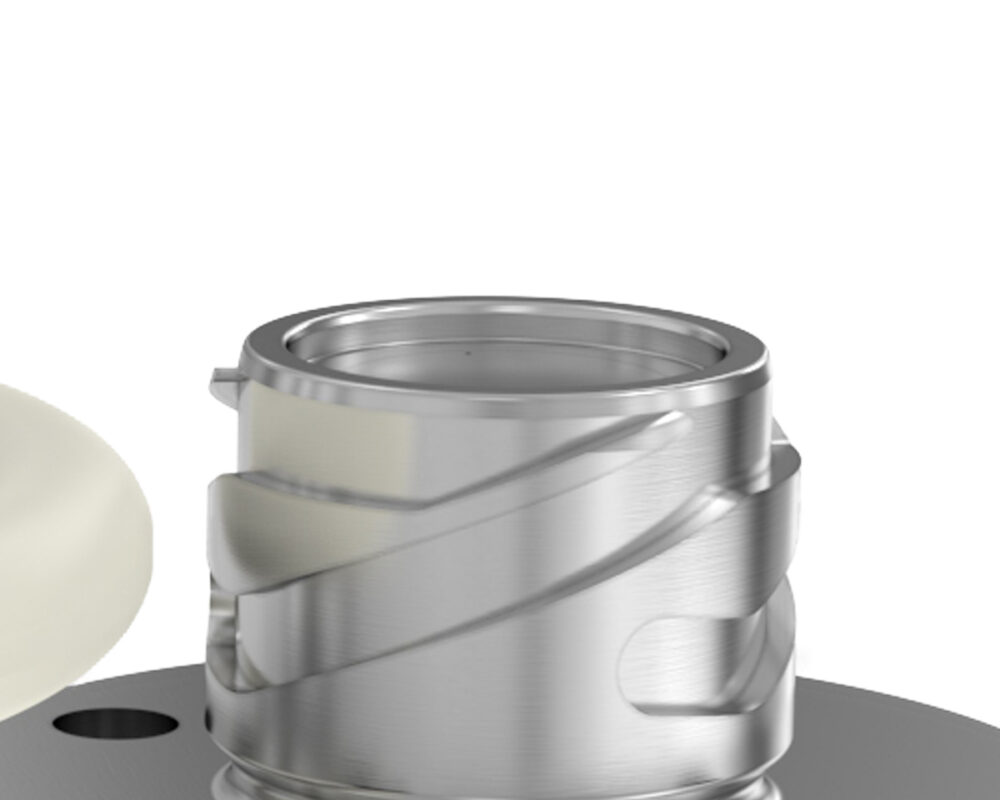

Compared with other dry couplings, all elements of the coupling mechanism are accommodated at the exterior part which is not in contact with the medium. Due to this optimization of dead spaces only a very small amount of medium can collect within the coupling. This results in a very good draining/cleaning ability and a clearly minimized risk of media contamination. The exterior positioning of the coupling mechanism also facilitates the cleaning process of the coupling.

| Size from: | 1”,1¼”, 1½”, 2”, 3”. |

| Material: | Stainless Steel, Hastelloy. |

| Seals: | FKM, NBR, FFKM, PTFE. |

| Working pressure | 25 bars. |

Benefits

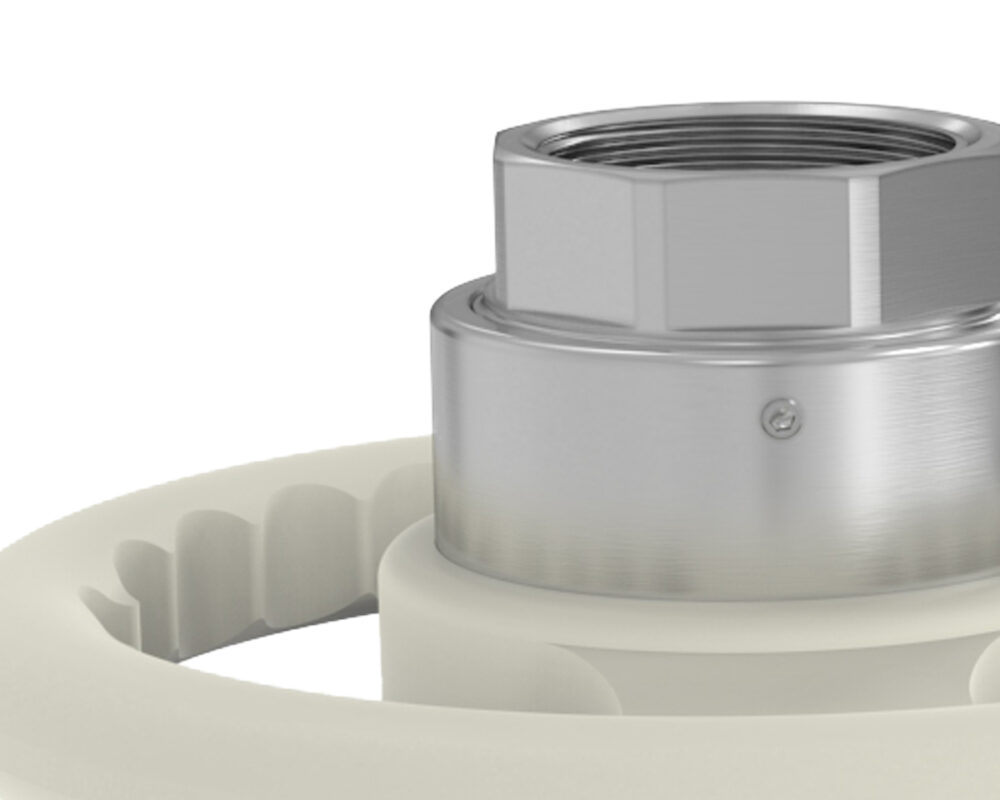

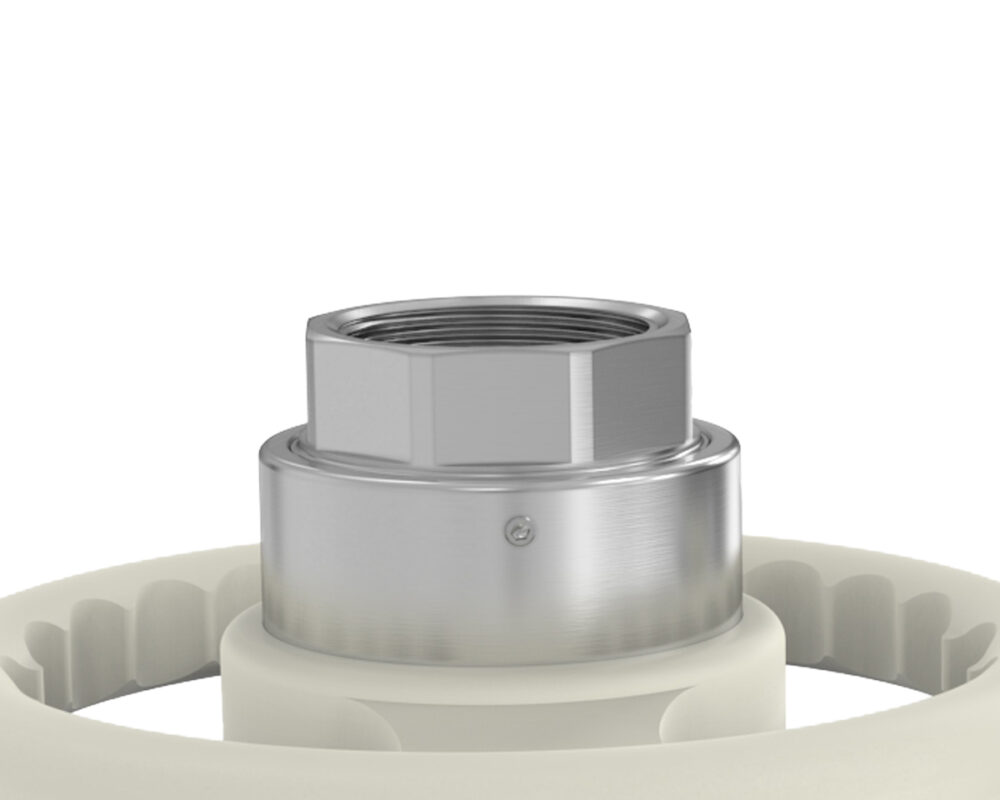

One-piece design

DEC with flange connection is in one-piece design - no screwed or welded flanges. Available in eccentric flange versions.

Minimal dead space

Minimal dead spaces and fewer parts in the media - easier to clean.

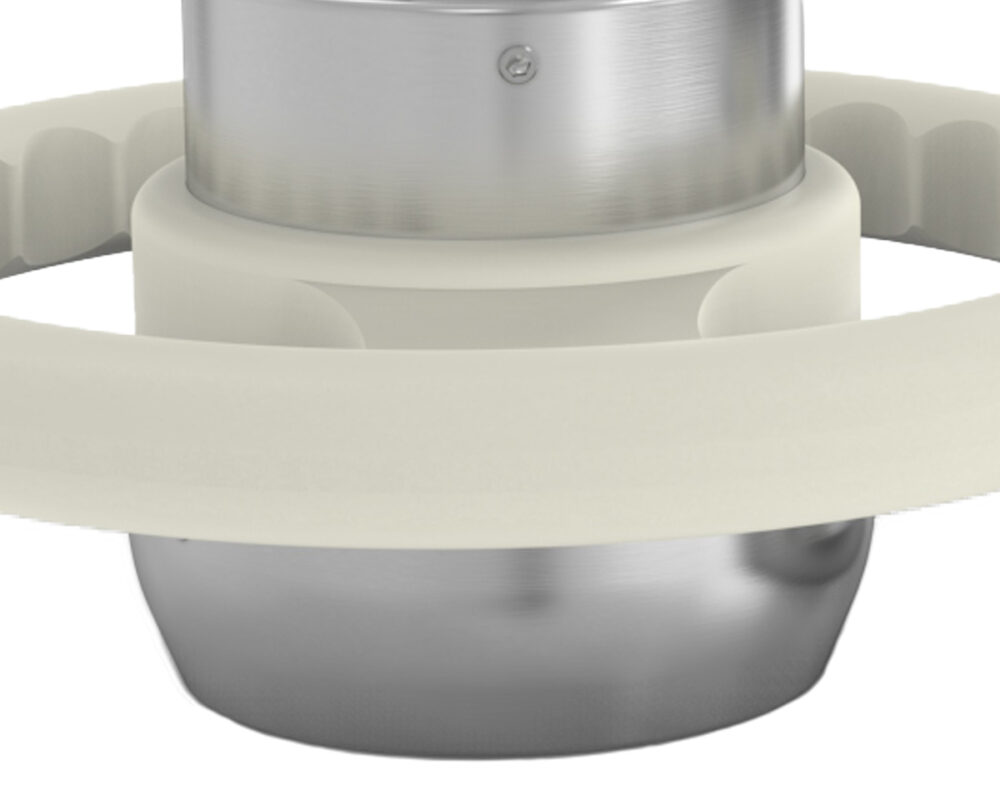

Handles

Handles also function as a protective ring. Composite (standard) or aluminum handles.

Solid bar material

Produced from solid bar material.

FDA-approved

All wetted parts FDA-approved.

Technical data

| Hose unit | Tank unit | Threaded connections | Flanged connections | Materials | Seals | |

|---|---|---|---|---|---|---|

|

|

1” (DN25) | BSP, NPT | EN | Specified in configurator | FKM, NBR, FFKM, PTFE |

|

|

1¼" (DN32) | BSP, NPT | EN | Specified in configurator | FKM, NBR, FFKM, PTFE |

|

|

1½” (DN40) | BSP, NPT | EN | Specified in configurator | FKM, NBR, FFKM, PTFE |

|

|

2” (DN50) | BSP, NPT | EN | Specified in configurator | FKM, NBR, FFKM, PTFE |

|

|

3” (DN80) | BSP, NPT | EN | Specified in configurator | FKM, NBR, FFKM, PTFE |

Service

Service guidance

Service guidance for a MannTek Dry evotek coupling.