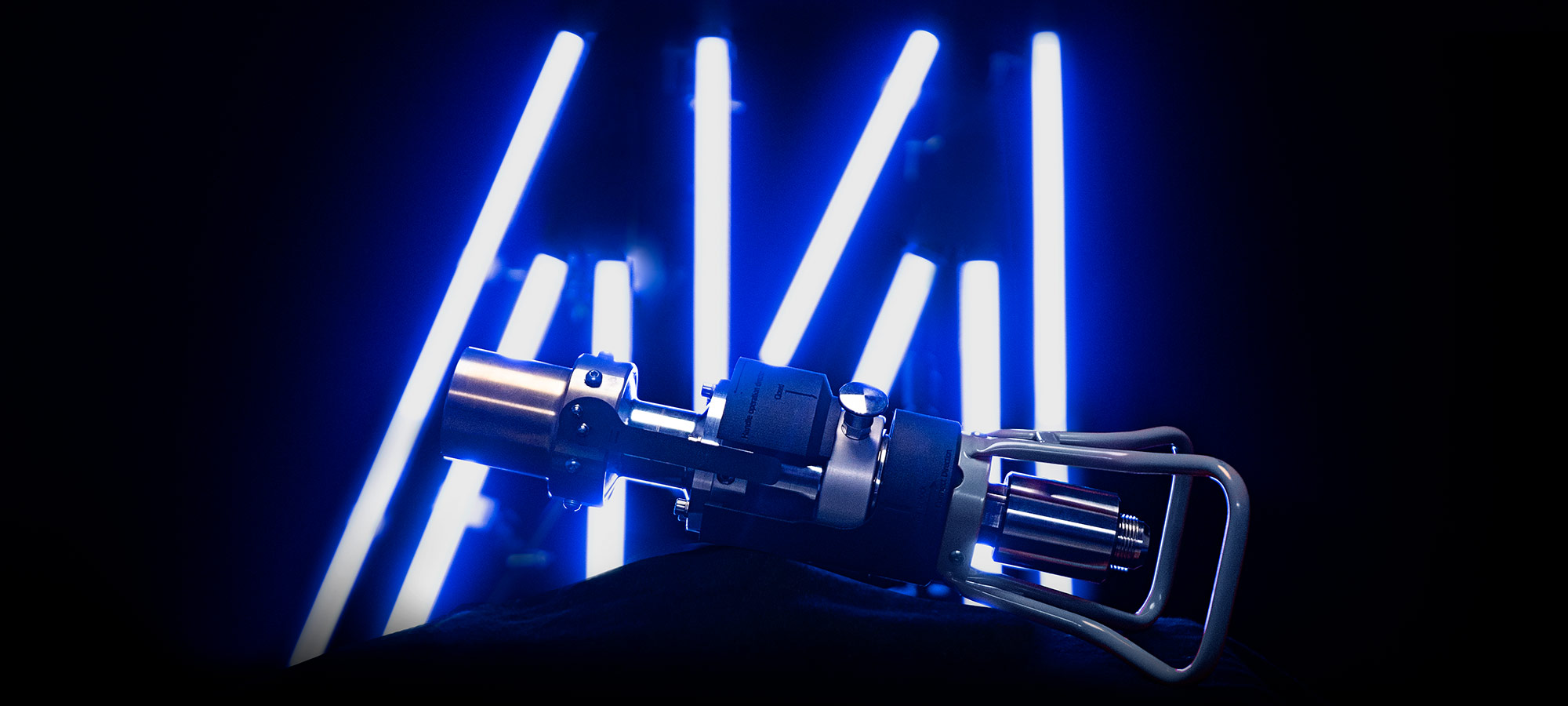

Quick and spill free connections for liquid hydrogen

MannTek has introduced LH2 (liquid hydrogen) solutions available for field testing, addressing a key gap in the distribution chain. The success lies in combining traditional liquid hydrogen handling with modern chemical couplings.

Hydrogen Q&A

How do we solve the challenges of extremely low temperatures? Which applications are our hydrogen solution suitable for, and how does our coupling work? These are some of the questions CEO of MannTek – Markus Bäckström – and our hydrogen expert and Technical Director – Gerhard Kopplin – answer on our hydrogen-themed Q&A.

Shorts

MannTek LH2 solutions are already available for field testing

While many experts are still busy talking about hydrogen as the fuel of the future, and big companies keep waiting for the politicians to create a legal framework for their investments, MannTek is already closing an important gap in the distribution chain of liquid hydrogen.

– The idea behind the new products is quite simple, says Gerhard Kopplin, Technical Director at MannTek. The combination of approved solutions from traditional liquid hydrogen handling and the connecting principle of modern chemical couplings made this concept successful.

As a joint development partner of well-known international operating gas companies, MannTek in Sweden has already solutions available for truck fuelling and ship bunkering. These are successfully verified with Liquid Hydrogen at independent laboratories, witnessed by third party inspections.

The first approved LH2 coupling for truck fuelling

The verifications led to the probably first approved LH2 coupling for truck fuelling based on the EC regulations 79/2009 and 406/201 for hydrogen powered motor vehicles. And by the end of 2021, the Clean Energy Partnership in Germany published a white paper for Liquid Hydrogen Connectors based on the experience from the evaluation process of this solution. Target is the standardization of the interface on ISO level. Also, the Plan Approval process by DNV for ship bunkering is almost finalized and MannTek is waiting for the final Product Certificate.

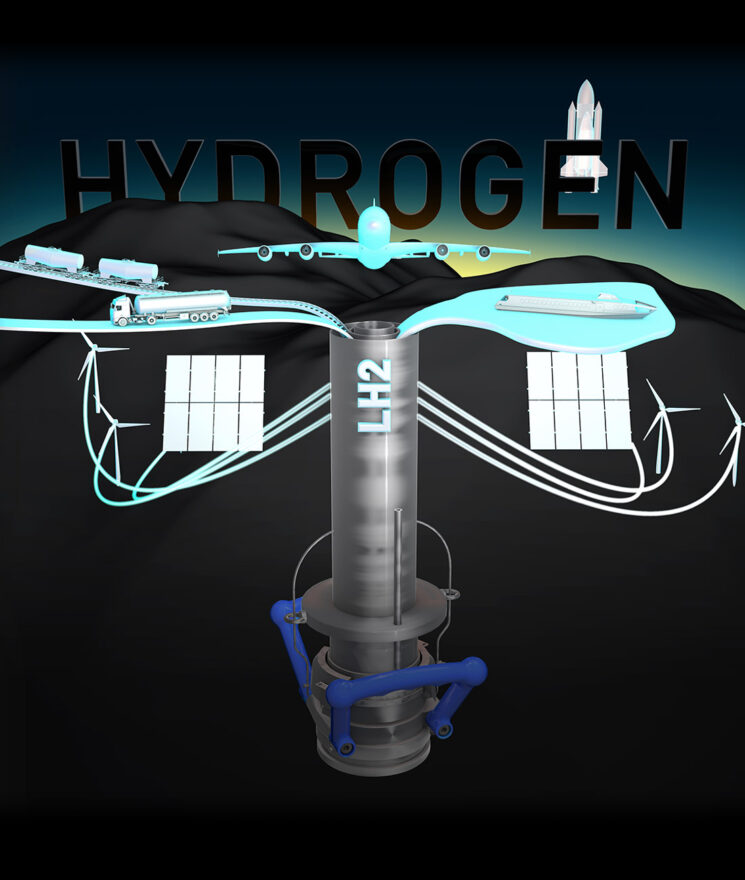

The first prototype for rocket re-fuelling

Both projects will go into operation already in 2022.

– Customers from all over the world are interested in testing the couplings for several different applications, says Gerhard Kopplin. Already in 2019, the first prototype for rocket re-fuelling has been successfully tested with liquid hydrogen.

– Other companies were showing nice 3D-models and interesting concept studies, we were producing hardware and testing. The new extended facilities in Mariestad with a big cryogenic testing area gave the right conditions to take this opportunity.

“We believe that liquid hydrogen applications will have an important place in the future energy infrastructure, and we are well prepared for it.”

Gerhard Kopplin, Technical Director at MannTek

Successful concept

The idea behind the new products is quite simple, according to Gerhard Kopplin.

– The combination of approved solutions from traditional liquid hydrogen handling and the connecting principle of modern chemical couplings made this concept so successful. Even if the temperature inside the coupling is reaching down to -253°C, the outer connecting mechanism is only exposed to ambient conditions.

Physical properties a real challenge

The high demand on the thermal isolation with heat intakes between 5 and 20 Watt is not only to protect the environment from the cold liquid.

– It is also to keep the heat outside to avoid boiling of the liquid inside, which may lead to rapid increase of the pressure.

– The extreme physical properties of hydrogen were a real challenge, Gerhard Kopplin explains, to meet the high demand on leakage rates from the rules and standards.

Right conditions and right partners

Creating the right conditions and finding the right partners to realize the complete hose package – including a proper vacuum insulation guaranteed down to 10-4 mbar over several years in operation – was a key factor to come to the point where we are today.

– We believe that liquid hydrogen applications will have an important place in the future energy infrastructure, says Gerhard Kopplin. And we at MannTek are well prepared.

If you want to learn more about our hydrogen solution, contact us at sales@manntek.se

Customer stories

Manntek plays a significant role in the building of the worlds first sLH2 refueling station.