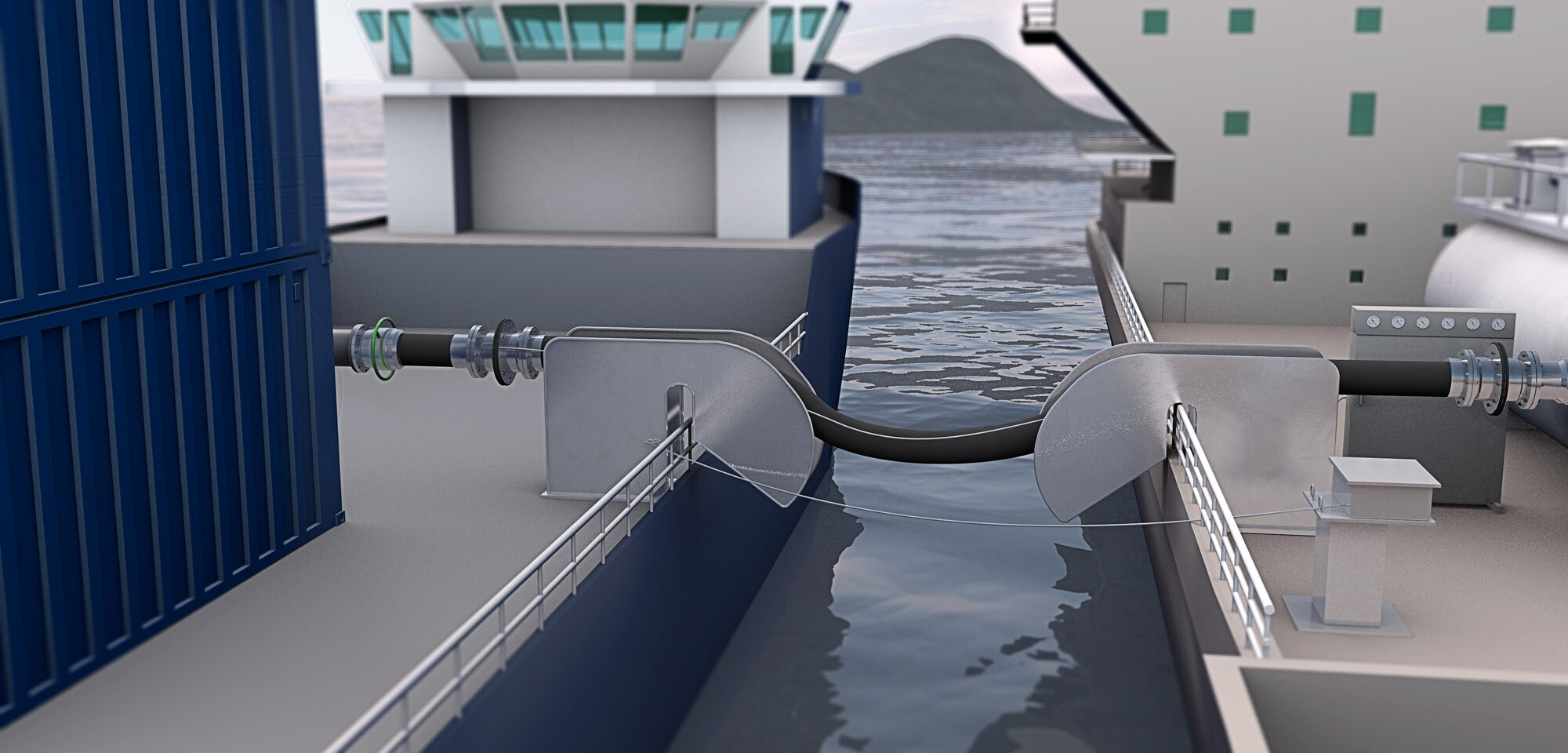

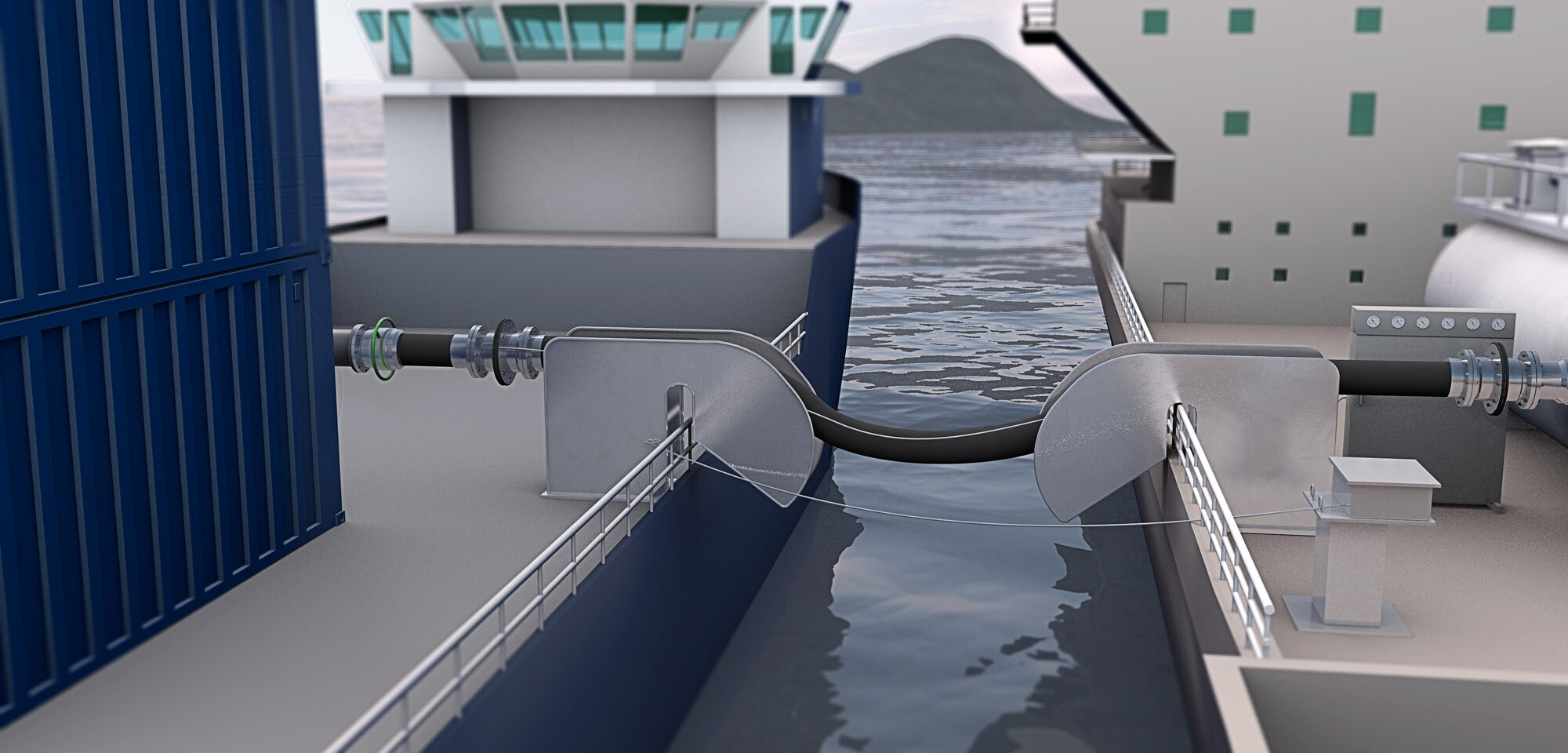

LNG Solutions

We are the leading manufacturer of LNG transfer and bunkering systems.

We are the leading manufacturer of LNG transfer and bunkering systems.

Subscribe to our newsletter to make sure you’ll be the first to know about what is happening at MannTek.

This page uses cookies

We use necessary cookies to make our website work correctly. We also use cookies to analyse visitor behaviours. If you want to change your cookie-settings click Edit or click Accept for all cookies.

Edit cookie settings

Manage cookie settings

These cookies are used to give you the best user experience. Improved function, personalization including the possibility to remember information that changes the websites look and behaviour, for example preferred language or region. They also include cookies to measure visitor traffic and to optimize the content, as well as cookies from third parties for targeted marketing.